Share to

Sucrose processing compound enzyme SN-105

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Description

-

Sucrose processing compound enzyme SN-105

Product Feature

Name of Product

Sucrose processing compound enzyme SN-105

Grade

Food Grade

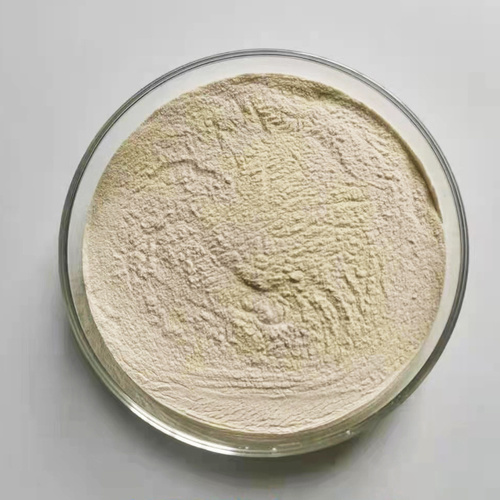

Appearance

White powder

Components

Alpha-glucanase, Beta -glucanase, amylase, cellulase, starch

Strain

Pichia pastoris, Trichoderma reesei

Production Method

Alpha - glucanase, Beta -glucanase, amylase, cellulase compound enzyme preparation products.

Working Condition

Temperature: 30-70℃, optimum 55-65℃;

pH: 4.0-7.0, optimum 4.5-5.5。

Application Field

Sugar cane, sugar beet as raw material sugar processing industry

Usage

Add directly into the crystallizer

Dosage

Add 0.1-0.3kg per ton of sugar juice, the most suitable amount to determine the need to test.

Efficacy

Enzymatic hydrolysis of glucan and starch in sucrose juice can reduce sucrose viscosity, accelerate crystal formation and improve crystallization efficiency.

It can reduce the viscosity of sucrose crystallization, improve the crystallization rate and gain sucrose yield.

Reduce the viscosity of sucrose juice, improve the fluidity of sugar juice, reduce the clogging of equipment, reduce the influence on the heat transfer of crystallization equipment, reduce energy consumption.

Enzymolysis of A-glucanase in sugar juice to reduce the influence of A-glucanase on product quality:

A If α -glucan cocrystallizes with sucrose, the application range of the product will be greatly reduced, so that chocolate and candy cannot maintain their normal form, and the beverage will not be clarified because of flocculent precipitate.

B in the determination of sucrose content, due to the presence of α -glucan, can lead to parameter error. The specific rotation of sucrose is [α]20D=66.6°, while the specific rotation of α -glucan with high left-handed rotation is three times as much as that of ordinary sucrose [α]20D=198°, resulting in the false rotation and hammerness, and a great disorder of material balance, and the normal production can not be carried out.

Product Specification

Activity(u/mL)

Alpha-glucanase≥40,000 Beta -glucanase ≥10,000 amylase≥5000 cellulase≥120

Pb (mg/kg)

≤5

Arsenic (in As)(mg/kg)

≤3

- coli(CFU/g)

≤30

Colon Bacillus(25g)

<10

Total count colony(CFU/g)

≤50000

Salmonella (25g)

Absent

Antimicrobial Activity( /g)

Absent

Loss on drying

≤8%

Packaging

25kgs/drum (or according to customer’s requirement)

Storage Condition

Shelf Life

12 months

Temperature

0-25℃

Storage Condition

This product should be stored in a dry place under 25℃, avoiding sunlight and direct contiguity with air for a long time.

Safety Information

Enzyme preparations belong to protein, which may induce sensitization and cause allergic type reactions in sensitized individuals. Prolonged contact may cause minor irritation for skin, eyes or mucous membrane of nose, so any direct contiguity with human body should be avoided. Details please refer to Material Safety Data Sheet.

Sucrose processing compound enzyme SN-105

Products Category

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products