Fermentation process: explanation of main factors affecting high-density fermentation of engineered bacteria (E. coli) (recombination)

Mar 31,2021

Several main factors affecting the high-density fermentation process of genetically engineered bacteria include the construction of recombinant bacteria, culture conditions, growth inhibitory factors and their control technologies. High-density fermentation can increase the cell growth density and the expression content of the target protein. In the high-density fermentation process, some harmful byproducts of inhibiting metabolism will be produced, but the impact can be reduced by feeding in batches.

A few factors affecting the construction of recombinant Escherichia coli

1.1 Selection of host bacteria

Different E.coli strains have great differences in culture conditions and foreign gene expression ability.The commonly used Escherichia coli BL21(DE3)plysS has a small plasmid encoding T7 lysozyme,which effectively reduces the expression of miscellaneous proteins,but does not affect the expression level of the target protein induced by IPTG,making it the most commonly used in recent years.Host bacteria.There are three pathways for the formation of expression products in E.coli:first,to form a stable natural conformation,which is soluble and active,and is not easily degraded;second,the protein is soluble,but the conformation is unnatural and easy to be intracellular Various proteases recognize degradation;third,the polypeptide chains aggregate with each other to form insoluble inclusion bodies,and are protease-resistant.Therefore,the selection of different host bacteria plays a vital role in the accumulation of expression products and downstream separation and purification.

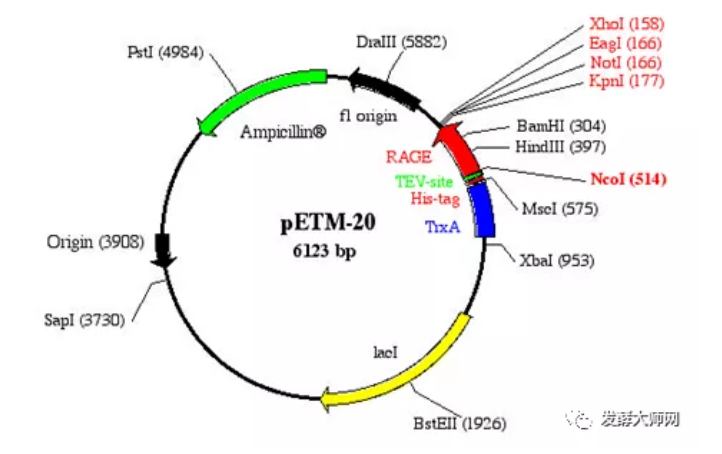

1.2 Plasmid vector

The plasmid vector constructed in recombinant Escherichia coli also has a great influence on the expression of foreign genes.Commonly used gene expression vectors include pET,pSC,pPBB,pUC series and a series of optimized vectors derived from them.The copy number and stability of plasmid vectors are not only affected by the physiological conditions and growth environment of the host bacteria,but also depend on their own genetic characteristics.The copy number of plasmid vectors is not as high as possible,because some cloned coding genes,when high-copy number plasmids are used as vectors,their product content is too high,which will seriously disrupt the normal metabolic activities of host cells.Plasmid instability usually has the following two conditions:(1)isolation instability;(2)structural instability.In addition,environmental conditions will also affect the copy number of the plasmid.For example,the limited supply of factors such as glucose and NH4+and changes in pH will cause a decrease in the copy number of the plasmid.

2.Cultivation conditions(nutrient source,control conditions)

2.1 Nutrition source

High-density fermentation requires high biomass and high-concentration expression products to be invested in a substrate several times the biomass to meet the needs of rapid growth and reproduction of bacteria and large-scale expression of gene products.The generally used medium is a semi-synthetic medium,and the concentration and ratio of each component of the medium should be appropriate.Excessive nutrients will inhibit the growth of bacteria,especially the ratio of carbon source and nitrogen source.Glucose(Glu)has been widely used as a restrictive substrate for high-density fermentation of recombinant bacteria due to its rapid utilization and low price and easy availability by bacteria.Generally,the Glu concentration is controlled at about 10g/L,if it exceeds 20g/L,cell growth will be inhibited.At the same time,people have used glycerol instead of Glu as the carbon source for bacterial growth to reduce the accumulation of acetic acid,which is a metabolic inhibitor,and it is easier to achieve high density of recombinant bacteria and high expression of foreign proteins.NO3-,tryptone(Tr),yeast extract(Ye)as nitrogen sources are conducive to cell growth.

2.2 Control conditions

2.2.1 Inoculation amount

The control of the size of the inoculum plays an important role in the culture of many cells and the accumulation of metabolites.The amount of inoculation has little effect on gene expression,but it has a significant effect on the growth of bacteria.When the inoculum amount is small(0.5%-4%),the specific growth rate is large,and the logarithmic growth period lasts for a long time;when the inoculation amount is large(>8%),the bacteria reach the stable period quickly and the continuous growth time is short.Autolysis is also fast,so the inoculum amount is generally selected below 4%.

2.2.2 Dissolved oxygen concentration

Dissolved oxygen concentration is one of the important factors that affect the growth of bacteria in the process of high-density fermentation.The growth and metabolism process of Escherichia coli requires the participation of oxygen.The concentration of dissolved oxygen has a great influence on the growth of bacteria and the production of products.If the concentration of dissolved oxygen is too high or too low,it will affect the metabolism of bacteria.In the process of high-density fermentation,due to the high density of the bacteria,the oxygen uptake of the fermentation broth is large.Generally,the amount of dissolved oxygen is increased by increasing the stirring speed and increasing the air flow.With the extension of the fermentation time,the cell density increases rapidly,and the dissolved oxygen concentration decreases accordingly.Therefore,in the later stage of high-density fermentation,it is necessary to maintain a high level of dissolved oxygen concentration.

At present,the main method to increase the amount of dissolved oxygen is to pass in pure oxygen to increase the oxygen transmission level,but it may cause uneven local mixing,which is easy to poison microbes with oxygen;clone the hyaluronan protein with the ability to improve oxygen transmission in the bacteria.(VHB);H2O2 is added to the medium,and the catalase of the host bacteria is used to decompose to produce O2;increase the partial pressure of oxygen.

2.2.3 pH value

Stable pH value is a necessary condition to keep the bacteria in the best growth state.Because the external pH value changes will change the pH value in the bacterial cells,thereby affecting the metabolic reaction of the bacteria,and then affecting the cell biomass and gene product expression.The organic acid(mainly acetic acid)produced during the fermentation of Ecoli can cause the pH of the fermentation broth to decrease,and the CO2 released by the cells dissolves in the fermentation broth and the carbonic acid produced by the interaction of H2O will also cause the pH of the fermentation broth to decrease.Under high-density fermentation conditions,the cells produce a large amount of acetic acid and CO2,which can significantly reduce the pH value.The pH value must be adjusted in time to keep it within the appropriate H value range to avoid the adverse effects of drastic changes in the pH value on cell growth and metabolism.

In the process of bacterial growth and product synthesis,the acid and alkali commonly used to control pH are HCl,NaOH and ammonia,among which ammonia is often used because it also has the effect of supplementing nitrogen sources.However,some studies have found that the NH4+concentration has a great influence on the growth of E.coli.When the NH4+concentration is higher than 170 mmol/L,it will seriously inhibit the growth of E.coli.

2.2.4 Temperature

Culture temperature is an important factor that affects bacterial growth and regulates cell metabolism.Higher temperature is conducive to high-density fermentation of bacteria,low-temperature culture can increase the expression of recombinant products,and the use of different culture temperatures in different culture stages is conducive to increasing the growth density of bacteria and the expression of recombinant products,and can shorten the culture cycle.However,when the temperature of cell growth suddenly increases,certain heat shock proteins are produced in the cells to adapt to the changing environment,and the relative amount of foreign proteins decreases,which makes subsequent purification difficult.If the range of temperature increase is not too large,the rate of heat shock protein synthesis will quickly decrease and normal protein synthesis will resume.For recombinant bacteria that use temperature to regulate gene expression or plasmid replication,the fermentation process is generally divided into two stages,growth and expression,and different culture temperatures are maintained respectively.But it will also cause the loss of plasmids due to heating,and reduce the amount of recombinant protein.

2.2.5 Inducer and induction time control

lactose gene(lac)and its derived promoters are widely used in the expression and production of recombinant proteins in the E.coli expression system.Such promoters usually use isopropyl-β-D-thiogalactoside(IPTG)as an inducer to express foreign proteins,but it is expensive and pollutes the environment,so it is not suitable for industrial production.Some people have used lactose instead of isopropyl-β-D-thiogalactoside(IPTG)as an inducer or mixed in a certain proportion to induce the expression of foreign proteins.

The amount of inducer added and the cell density during induction will affect the expression level of foreign protein.When the concentration is low,the expression level of the exogenous protein increases continuously with the increase of the concentration of the inducer;when the concentration exceeds a certain limit,it will affect the metabolism of the bacteria and the level of protein expression.

The choice of induction time is also an important factor affecting the expression of foreign proteins.It is generally controlled in the logarithmic growth phase or the mid-to-late logarithmic period of the bacteria.

2.2.6 Feeding control

The key to the successful high-density fermentation of recombinant E.coli lies in the feeding strategy,that is,the use of reasonable nutrient feeding methods.Commonly used flow feeding modes:non-feedback feeding and feedback feeding.The main working principles are shown in the table below.

In addition to the influence of feeding technology,the selection of feeding medium composition and feeding time is also crucial to the expression of foreign genes.

Three growth inhibitors(acetic acid,carbon dioxide)

3.1 Accumulation of acetic acid

The growth of E.coli with Glu as a carbon source is often accompanied by the secretion of acetic acid,which in turn affects cell growth and protein expression.The secretion of acetic acid can reduce the synthesis metabolism by maintaining a lower concentration of Glu.When the residual Glu concentration is<1g/L and the acetic acid concentration is<2g/L,there is no inhibitor of E.coli cell growth.

"The production of acetic acid is related to the electron transport chain in the cell and the tricarboxylic acid cycle.At present,overseas studies hope to change the metabolic pathway of recombinant E.coli through metabolic engineering,thereby reducing the production of acetic acid.

3.2 CO2 accumulation

During high-density fermentation,the accumulation of bacterial metabolite CO2 will also inhibit the expression of foreign proteins.Because CO2 has a direct toxic effect on the bacteria,and dissolving in the fermentation broth will also cause the pH to drop.It has been reported that Anabaena variabilis can use CO2 as a carbon source for high-density cultivation,which can eliminate the inhibitory effect of CO2.